Metal Random and Structured Packing

Several different, more refined versions of the original raschig ring are available today. Metal column packings tend to be used in processes that involve higher temperatures, such as distillation.

Column packings made out of metal can provide much better temperature resistance than plastic packings. Some high temperature wet scrubbing and air stripping applications also use metal packings for this reason, especially those that steam clean their packing to destroy biological growth.

Pictured below are several popular metal random packings that Raschig USA offers. Each image links to a handout with more information.

Random Packings: Metal

The Raschig Super Ring® Plus

The Raschig Super Ring®, refined. This 5th generation column packing promotes further performance increases over its older sibling. This helps to further reduce the size of a planned column, or increase the capacity of an existing column. Whether it is decreasing costs (Smaller column/pressure drop) or increasing bottom line (Increased production), this ring can help.

The Raschig Super Ring®

The 4th generation in random packing design. It offers significantly lower pressure drop and equal or superior mass transfer properties vs. traditionally designed random dump metal tower packings.

Pall Rings (Jaeger Rings, Ballast Rings, Basic Rings, etc.)

Traditional random packing for multiple applications.

Raschig Rings

The original random packing invented by Dr. Raschig. There are more optimized packings available today, but it’s a classic.

Structured Packings: Metal

Structured metal packings are available too. Structured packings tend to offer lower pressure drop and increased capacity when compared to random packings discussed above. Structured packings must be designed and constructed to specific columns.

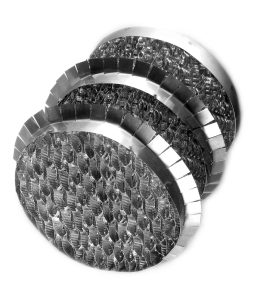

Raschig Super-Pak®

The Raschig Super-Pak® is a structured packing designed to allow free flow of vapor – liquid streams. Unlike previous structured packing design, there are no sharp directional flow changes within the Raschig Super-Pak® element. Rows of sinusoidal waves within the vertical packing sheets are surface-enhanced to encourage greater turbulent radial spread of thin liquid film flows on the front and back of the waves on each sheet within a packing element. The open structure of Raschig Super-Pak® achieves excellent hydraulic and mass transfer efficiency characteristics. Loading capacity is high, with improved separation, yet pressure drop remains low during normal operation.

General Information for Metal Packing

Articles on the Raschig Super Ring®:

-

“Researching Rings” Dr. Michael Schultes

-

Fractionation Research Institute, Inc.

Articles on Raschig Super-Pak®:

Raschig Super Ring® and Raschig Super-Pak® are registered trademarks of Raschig USA, Inc.